Depending on local environmental conditions, their projected life could span 50 to 60 years and beyond. Low Maintenance: Because of the inherent strength, durability, and longevity of IMPs, they typically require minimal maintenance.

Similarly, Are insulated metal panels structural?

What are Structural Insulated Panels? Compared to traditional framing lumber with cavity insulation, structural insulated panels, or SIPs, are a durable and energy-efficient building material most often used in residential and light commercial applications.

How thick are insulated metal panels? How thick is an insulated metal panel? Insulated metal panels can be as thin as 1 inch, or as thick as 8 inches for cold storage wall panels. Most IMPs for commercial buildings are in the 1 inch – 6 inch range.

Thereof, What are insulated metal panels?

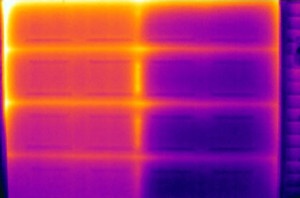

Insulated Metal Panels (IMPs) are lightweight composite exterior wall and roof panels with metal skins and an insulating foam core.

What are insulated wall panels used for?

Because of the above named properties, today insulated panels are particularly popular for lightweight construction of halls, roofs for residential buildings, but also as insulation panels for insulating or also as sound proofing in drywall construction.

How do you build an insulated metal panel?

How much are insulated wall panels?

Structural Insulated Panel Prices

| PANEL THICKNESS inches | R-Value | PRICE per SQFT |

|---|---|---|

| 4.625 | 16 | $10.69 |

| 6.5 | 24 | $11.38 |

| 8.25 | 32 | $12.16 |

What are the advantages of structural insulated panels?

Insulation

SIPS buildings are generally more energy efficient, stronger, quieter and more airtight than older technologies. Less air leakage means less drafts, fewer noise penetrations and significantly lower energy bills, thus a reduction in CO2 emissions.

How do you cut insulated panels?

Cutting insulated panels

For this purpose, the panels must be placed on a firm base and cut with a plunge saw, jigsaw or circular saw. It is important to make sure that the cutting surface does not become too hot during cutting. This could lead to the galvanization, and thus the corrosion protection, burning.

How do I install Kingspan insulated panels?

How do you install tin wall panels?

Do SIPs save money?

Building with SIPs leads to monthly savings through lower utility bills. A small amount of money invested in building better with SIPs, adds up over time up to create a handsome rate of return. Over time, you will definitely save money building with SIPs.

Can you build your own SIP panels?

If you can build with sticks, you can build with RAY-CORE SIPs ®. Uses standard framing practices, no special plans, no expensive engineering, no specialized builders, no costly cranes. « Easy-peasy »!

How much do SIP panels Cost Canada?

An approximate installed cost for the 8-1/4” SIP wall, including lumber, sealants, and labor is $6.40 per square foot; a 10-1/4” EPS SIP wall of the same area would cost approximately $7.40 per square foot (LeRoy 2009).

What are the disadvantages of using structural insulated panels?

The big disadvantage of SIPs is moisture resistance. They can be damaged by moisture, and require special and careful protection. You need to install additional panel or waterproof surface. Pest resistance is another problem.

What is SRC panel?

The SRC Panel System is a composite sandwich type structural panel composedof high tensile wires densely welded together, an expanded polystyrene (EPS)core, and concrete panels for exterior faces. The steel reinforced concrete panelsprovide tensile and compressive strength.

What are the advantages and disadvantages of SIPs?

Like any other construction method, SIPs have their fair share of pros and cons. The key pros include energy efficiency, structural superiority, ease of construction, and eco-friendliness. The main cons include pest, moisture damage, and ventilation issues, as well as low fire resistance.

How do you install insulated roofing sheets?

Can you cut insulated roof panels?

The insulated roofing panels come in standard sizes of 4 metres,, 5.9 metres, 7.8 metres and 11.8 metres. Any of these can be cut down to size for you.

How do you cut Cooldek?

How do you install architectural panels?

How do kingspan fit between rafters?

How do you install insulated roof sheeting?

How do you attach old tin to a wall?

How do you attach galvanized tin to a wall?

Start at the bottom of the wall, and install the first strip one inch above floor level. Install the rest of the strips 24 inches apart, and finish with an additional strip at the top of the wall. Insert a screw in a furring strip every place it crosses a wall stud. Studs are typically 16 or 24 inches apart.

How do you attach sheet metal to a wall?

Apply a coat of contact cement to the back of the first aluminum sheet while the adhesive on the wall is still wet. Lift the sheet to the wall and press it against the drywall, aligning at least one side of the sheet with a stud. Hold the sheet in place for at least two minutes until the contact cement is secure.

Join TheMoney.co community and don’t forget to share this post !